5

Bearing Taxonomy – Part 1

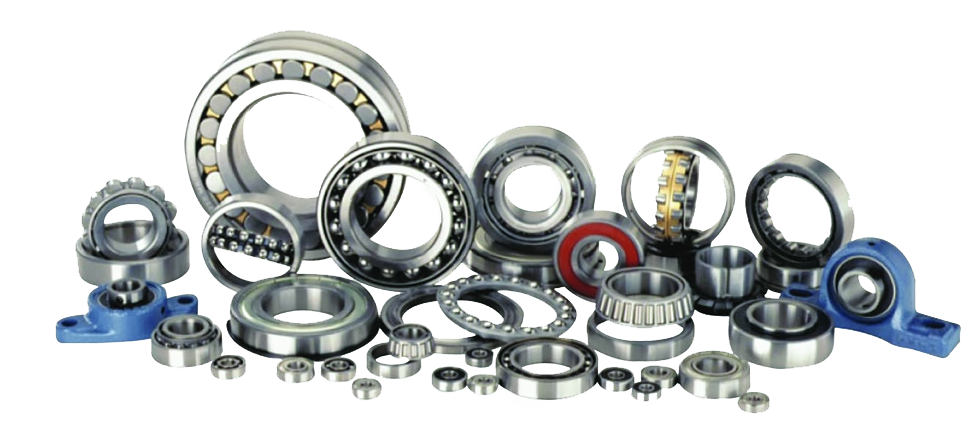

In this series of articles, ExaTech Global is proposing to shed some light on a few of the most popular types of bearings, their characteristics as well as their uses. Since a standard taxonomy for bearings does not exist, it is often difficult to find what you’re looking for simply because a company or commercial entity uses a different nomenclature. We tried to compile and use the most common of these names as they are in use in the industry.

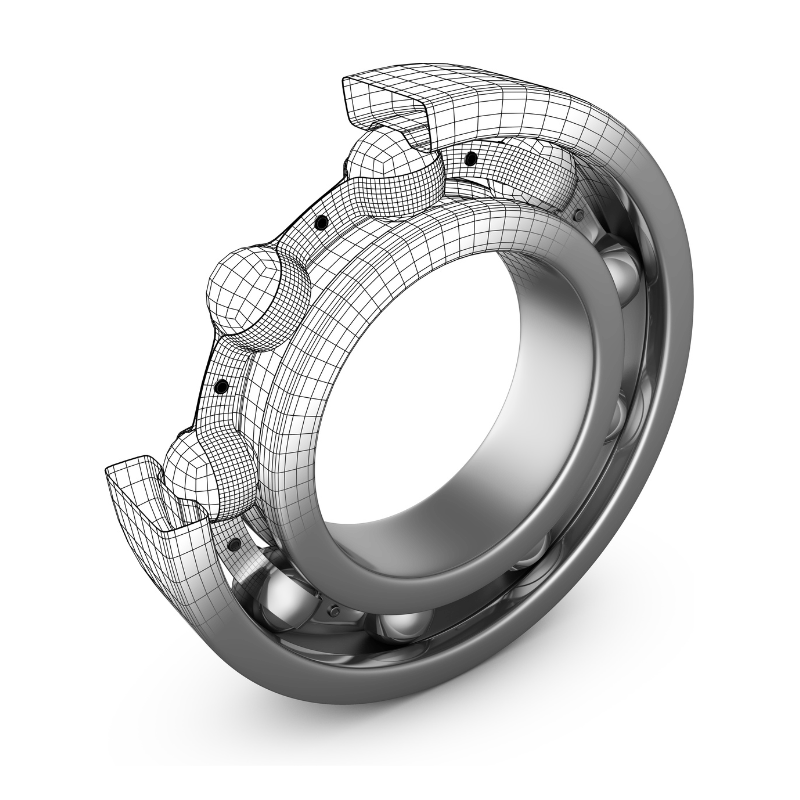

A bearing is a mechanical assembly (or device) with three main functions: it carries a load (hence the name “bearing”), it reduces friction and it positions moving parts. Ball bearings use balls manufactured from a variety of materials to separate two bearing rings in order to reduce surface contact and friction across moving planes. They ensure smooth, efficient operation in many machines with rotary motion, from car wheels, engines and turbines to medical equipment and toys – see the famous fidget spinners.

While wheeled vehicles started using plain bearings about 5000 BC and Leonardo da Vinci incorporated ball bearings in some of his devices in early 1500’s, the first modern recorded patent on ball bearing was awarded to Philip Vaughan from Camarthen, OK who created the first design for a ball bearing in 1794 (see the Wikipedia article for more details).

Since then, a number o different ball bearing type were invented, patented and manufactured; this category of devices are continuously improved upon. Since the basic design remained largely unchanged, the main differentiating factor between manufacturers is the material used to manufacture the bearing.

Ball bearings have a very wide area of application: household items such as bicycles, washing machines, food processors and fishing rods, various office equipment devices like photocopiers, fans, air-conditioners and more. Ball bearings are used on a large scale in different industries for manufacturing elevators, assembly lines, medical and dental equipment high-speed machine tooling, power tools, toy manufacturing to name a few.

One industry that makes heavy uses of different types of bearings is the automotive industry. From engines, steering assemblies and electric motors to gear boxes the use of bearings in the motor vehicle industry is a prime example of the importance of ball bearings as mechanical devices.

Some of the industry leaders today are: NSK Ltd. (Japan), NTN Corporation (Japan), Misumi Corp (Japan), Schaeffler Group (Germany), AB SKF (Sweden), Timken (USA), KML Bearing Canada Inc. but many emerging economies are starting to produce high-quality bearings contributing in a price reduction across the industry.

In Part 2 of this series, we will examine the entire taxonomy for ball bearings.